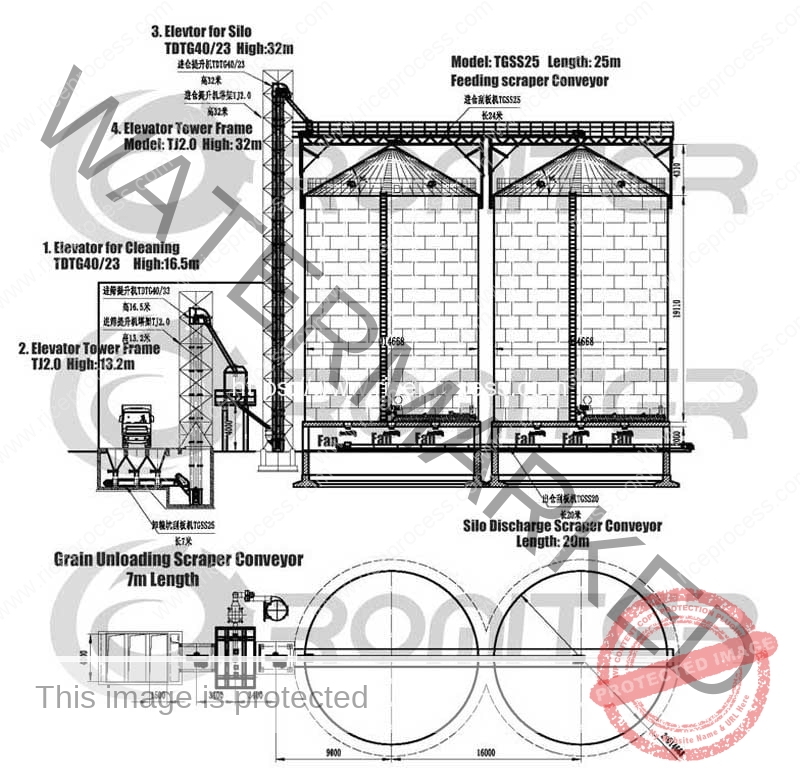

Product Details

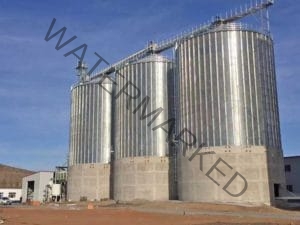

4000TON Paddy Rice Storage Steel Silo

Specification of 4000Ton Paddy Rice Storage Silo

| Item | Name | Description | Model | Qty | |

| Steel Silo Main Body | |||||

| 1 | Paddy Rice Storage Steel Silo | Silo Diameter:14.668m Volume:3434m3 Volume-Weight: 2500t Silo Total Height:22.61m(not include foundation height) Silo Height:19.11m; Silo Roof equipped with air window, man hole, guard bar, and ladder stand Silo equippped with silo door, platform, internal ladder and guard bar, outside ladder and guard bar Silo adopt high quality galvanized steel made, 275g/m3. We equipped with inner colomn |

TCK14617 3434m3 | 2 | units |

| 2 | Tower of Feeding Elevator | Angle Steel made, Each layer equipped with spiral staircase and rest platform(galvanized made). Double Side is with Armrest. Top is equiped with Hoisting Beam for repair |

TJ2.0*2.5 Height:32m | 1 | unit |

| 3 | Tower of Feeding Elevator to Cleaning Screen | Angle Steel made, Each layer equipped with spiral staircase and rest platform(galvanized made). Double Side is with Armrest. Top is equiped with Hoisting Beam for repair |

TJ2.0*2.5 Height:13.2m | 1 | unit |

| 4 | Vestibule for Steel Silo Roof | Width:12.5m Galvanized Made Fabricated Type |

TL125 Length:32.5m | 1 | unit |

| 5 | Vestibule Frame for Steel Silo Roof | Galvanized Made Fabricated Type |

ZJ146 | 4 | units |

| 6 | Induced Draft Fan of Steel Silo Roof | Each Silo 2Unit Axial Flow Fan | TCK146 | 4 | units |

| 7 | Air Circulation System | Each Silo 2unit 4-72No5A Fan, 15kw/unit Fan. Include Galvanized Ventilation Network Board |

TF146 | 2 | sets |

| 8 | Electronic Thermometer | Each Silo 7 line, each 7 have 10point temperature detect position. All the tempertaure data connect with computer | CW146 | 2 | sets |

| 9 | Material Levelling Device | Each Silo 1unit | ZXK Type | 2 | sets |

| Total | |||||

| Steel Silo Auxuiary Equipment | |||||

| 1 | Screen of Grain Unloading Pit | 4m*1.5m | 3 | units | |

| 2 | Cone Bucket of Grain Unloading | 4mm Steel Plate | 4m*1.5m | 3 | units |

| 3 | Manual Gate | Used for Grain Unloading Cone Bottom. Galvanized Made | FM300 | 3 | units |

| 4 | Scraper Conveyor for Grain Unloading | Hardened reducer, manganese steel bottom, chain is equipped with wear-resisting plate. galvanized made | TGSS25*7.5m 40T/H | 1 | unit |

| 5 | Double Drum Grain Primary Cleaner | 50T/H,Platform Height 4m | TCQYS100/250 | 1 | unit |

| 6 | Platform for Grain Primary Cleaner | Structural steel made plat form, Guard bar is made of galvanized round tube | 1 | set | |

| 7 | Pulse Dust Collector | Used for Primary Cleaner | TBLM78 | 1 | unit |

| 8 | Cyclone | Used for Primary Cleaner | Φ1200 | 1 | unit |

| 9 | Air Seal Machinery | Used for Primary Cleaner | TGFY16L | 2 | units |

| 10 | Dust Exhausting Fan | Used for Primary Cleaner | 4-72-4A | 1 | unit |

| 11 | Dust Duct | Used for Primary Cleaner | 1 | set | |

| 12 | Permanent Magnetic Drum | Stainless Steel | TCXT40 | 1 | unit |

| 13 | Impurity Articulated Chute | Galvanized Steel Lock Making | LG250,Length:8m | 1 | set |

| 14 | Articulated Chute | Galvanized Steel Plate Locking Made and internal wear-resisting plate | LG250 Length:9m | 1 | set |

| 15 | Elevator for Primary Cleaner | Height: 16.5m 50T/H,Drum is made of 2mm steel. Hardened reducer,first round plastic cover, anti-reversal, galvanized | TDTG40/23 | 1 | unit |

| 16 | Elevator for Silo | Height: 32m 50T/H,Drum is made of 2mm steel. Hardened reducer,first round plastic cover, anti-reversal, galvanized | TDTG40/23 | 1 | unit |

| 17 | Electric Valve | Used for Silo Feeding, Galvanized Made, Electricity Power | DFM250 | 1 | unit |

| 18 | Manual Point Valve | Used for Silo Grain Unloading, Galvanized Made | SDFM250 | 6 | units |

| 19 | Scraper Conveyor of Grain Feeding | Length: 24.5m 50T/h. Hardened reducer, manganese steel bottom, galvanized made | TGSS25 | 1 | unit |

| 20 | Scraper Conveyor of Silo Unloading | Length: 30m 30T/h. Hardened reducer, manganese steel bottom, galvanized made | TGSS20 | 1 | unit |

| 21 | Buffer | Galvanized Made | 3 | units | |

| 22 | Control Cabinet | Include Control Cabinet, Cable, Galvanized Crane Span Structure etc. | 1 | set | |

| 23 | Auxiliary Materials | Acetylene, Welding Rod, Oil Paint, Air Pipe, Manual Board etc | 1 | set | |

| 24 | Total | ||||

| Total Power Consumption 104.8KW | |||||